For the two astronauts who had actually simply boarded the Boeing “Starliner,” this journey was really aggravating.

According to NASA on June 10 regional time, the CST-100 “Starliner” parked at the International Space Station had an additional helium leak. This was the 5th leakage after the launch, and the return time needed to be held off.

On June 6, Boeing’s CST-100 “Starliner” came close to the International Spaceport station during a human-crewed flight test goal.

From the Boeing 787 “Dreamliner” to the CST-100 “Starliner,” it carries Boeing’s expectations for the two significant fields of aviation and aerospace in the 21st century: sending people to the skies and after that outside the atmosphere. Unfortunately, from the lithium battery fire of the “Dreamliner” to the leak of the “Starliner,” numerous technological and quality problems were revealed, which appeared to show the inability of Boeing as a century-old factory.

(Boeing’s CST-100 Starliner approaches the International Space Station during a crewed flight test mission. Image source: NASA)

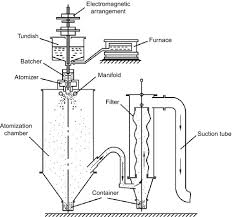

Thermal spraying innovation plays a crucial function in the aerospace field

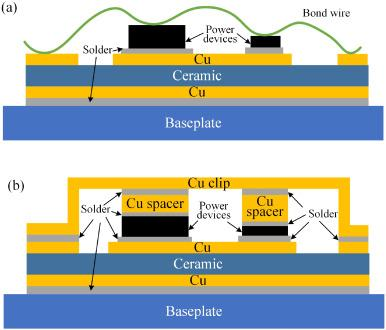

Surface conditioning and security: Aerospace vehicles and their engines run under severe conditions and need to face multiple difficulties such as heat, high stress, high speed, corrosion, and wear. Thermal spraying technology can significantly boost the service life and dependability of crucial parts by preparing multifunctional coverings such as wear-resistant, corrosion-resistant and anti-oxidation on the surface of these parts. For instance, after thermal spraying, high-temperature area components such as generator blades and burning chambers of aircraft engines can stand up to greater running temperature levels, lower maintenance costs, and extend the overall life span of the engine.

Upkeep and remanufacturing: The upkeep price of aerospace devices is high, and thermal spraying technology can swiftly fix worn or damaged parts, such as wear repair of blade edges and re-application of engine inner coatings, decreasing the requirement to change repairs and saving time and price. Furthermore, thermal splashing likewise sustains the efficiency upgrade of old parts and realizes efficient remanufacturing.

Lightweight design: By thermally spraying high-performance finishes on light-weight substratums, products can be offered extra mechanical buildings or unique features, such as conductivity and heat insulation, without adding excessive weight, which meets the urgent needs of the aerospace field for weight decrease and multifunctional combination.

New material development: With the advancement of aerospace technology, the requirements for product efficiency are enhancing. Thermal splashing innovation can transform conventional materials into layers with unique homes, such as gradient finishes, nanocomposite finishings, and so on, which advertises the research advancement and application of brand-new products.

Customization and flexibility: The aerospace field has strict requirements on the size, shape and function of parts. The adaptability of thermal splashing innovation permits layers to be personalized according to certain needs, whether it is complex geometry or unique performance requirements, which can be attained by precisely managing the coating thickness, composition, and framework.

(CST-100 Starliner docks with the International Space Station for the first time)

The application of spherical tungsten powder in thermal spraying modern technology is primarily as a result of its one-of-a-kind physical and chemical homes.

Covering harmony and density: Spherical tungsten powder has great fluidity and reduced certain area, that makes it less complicated for the powder to be equally distributed and melted throughout the thermal splashing procedure, therefore forming a more uniform and thick finishing on the substratum surface area. This finish can offer better wear resistance, corrosion resistance, and high-temperature resistance, which is essential for key elements in the aerospace, energy, and chemical industries.

Enhance finishing performance: Making use of round tungsten powder in thermal splashing can dramatically enhance the bonding strength, put on resistance, and high-temperature resistance of the finishing. These advantages of spherical tungsten powder are specifically crucial in the manufacture of burning chamber layers, high-temperature component wear-resistant coverings, and other applications due to the fact that these components operate in extreme settings and have exceptionally high product efficiency needs.

Minimize porosity: Compared with irregular-shaped powders, round powders are most likely to lower the formation of pores during piling and thawing, which is incredibly beneficial for finishings that require high securing or deterioration penetration.

Suitable to a range of thermal splashing innovations: Whether it is fire spraying, arc spraying, plasma splashing, or high-velocity oxygen-fuel thermal spraying (HVOF), round tungsten powder can adjust well and show excellent procedure compatibility, making it simple to select the most suitable splashing modern technology according to various needs.

Unique applications: In some unique areas, such as the manufacture of high-temperature alloys, finishes prepared by thermal plasma, and 3D printing, spherical tungsten powder is additionally made use of as a support phase or straight constitutes a complicated structure component, additional widening its application range.

(Application of spherical tungsten powder in aeros)

Provider of Spherical Tungsten Powder

TRUNNANO is a supplier of tellurium dioxide with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about 2 tungsten cube, please feel free to contact us and send an inquiry.

Inquiry us