In a major jump in commercial lubricants, an introducing products scientific research business has introduced its most recent innovation: a heat-treated molybdenum disulfide (MoS æ) powder. This sophisticated formula is expected to redefine performance requirements in extreme pressure and high-temperature settings, offering unmatched rubbing reduction and wear resistance.

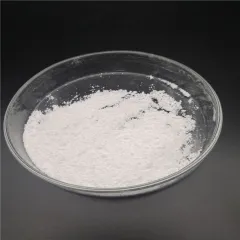

(Hot molybdenum disulfide powder)

The pioneering molybdenum disulfide powder undergoes a proprietary heat treatment process to modify its microstructure, making its item significantly superior to traditional molybdenum disulfide lubes. The chief executive officer of the company specified, “Also under the worst problems, our hot MoS æ powder can keep its honesty and is extremely appropriate for applications such as aerospace engineering and hefty machinery.

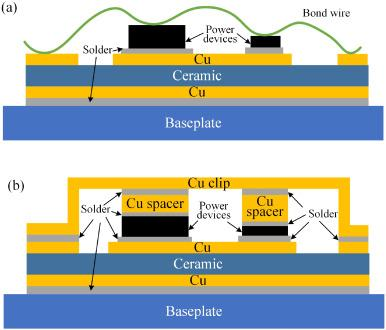

The individuality of warm MoS æ powder hinges on its enhanced surface activity, which helps to create self-healing, low-friction layers on metal surfaces. This not just minimizes upkeep prices and downtime but likewise assists enhance power performance and extend tools life-span.

One of one of the most significant applications remains in the field of renewable energy, where wind generators running in offshore settings encounter major rust and lubrication challenges. Reed included, “Our powder shows extraordinary flexibility against saltwater deterioration and significantly improves the performance of turbine gears.”

This development is at a defining moment when various markets are looking for eco-friendly choices to conventional lubes. Molybdenum disulfide powder offers a sustainable remedy as it can hold up against severe conditions without destruction, decreasing the requirement for constant reapplication and therapy.

The company is already working closely with numerous multinational companies to integrate warm molybdenum disulfide powder into its manufacturing procedure. Early adopters in the automotive and production sectors reported a significant boost in productivity and a decline in equipment failing rates.

As the world drives more lasting and effective technologies, warm MoS æ powder demonstrates the power of material development in overcoming long-lasting commercial challenges. As research aimed at additional enhancing its efficiency proceeds, the future of high-performance lubrication looks increasingly appealing.

Regarding Metalinchina

Metalinchina is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality metals and metal alloy. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, Metalinchina dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for zinc dust, please send an email to: nanotrun@yahoo.com

Inquiry us